Benefits, Uses, and Types of Corrugated Boxes: Detailed Guide

2025-04-09 07:44:26

People now prefer online shopping over in-store shopping. And this is why brands look for protective packaging to ensure they deliver products in pristine condition to customers. Corrugated packaging is one of the best options when it comes to shipping products safely over long distances. What makes corrugated boxes popular for shipping products safely is their sturdy construction. They can be customized in every shape, style, and design. Read this blog to explore uses, benefits, and types of corrugated boxes!

What Are Corrugated Boxes?

Before understanding the types of corrugated boxes, know what they actually are. Corrugated box packaging is extensively used to ship items over long distances. They are versatile and can be used for various purposes.

For example, large corrugated cartons are used to ship heavier and bulkier items. Small to medium mailer boxes are used to ship retail products like cosmetics, shoes, and apparel. 95% of all goods consumed in North America are shipped in corrugated box packaging. Also, 40% of all corrugated boxes produced annually are used to package food and beverages.

How is Corrugated Cardboard Made?

Corrugated box packaging is made from multiple layers of card stock and kraft flutes to ensure strong construction. A corrugation machine is used to create wavy kraft flutes to make corrugated cardboard. The lining of kraft flutes can be done between every two layers of card stock. A thin corrugated kraft flute is used between the thick kraft paper or cardstock layers. The number of cardstock or kraft paper walls depends on the product you want to package in the corrugated box packaging.

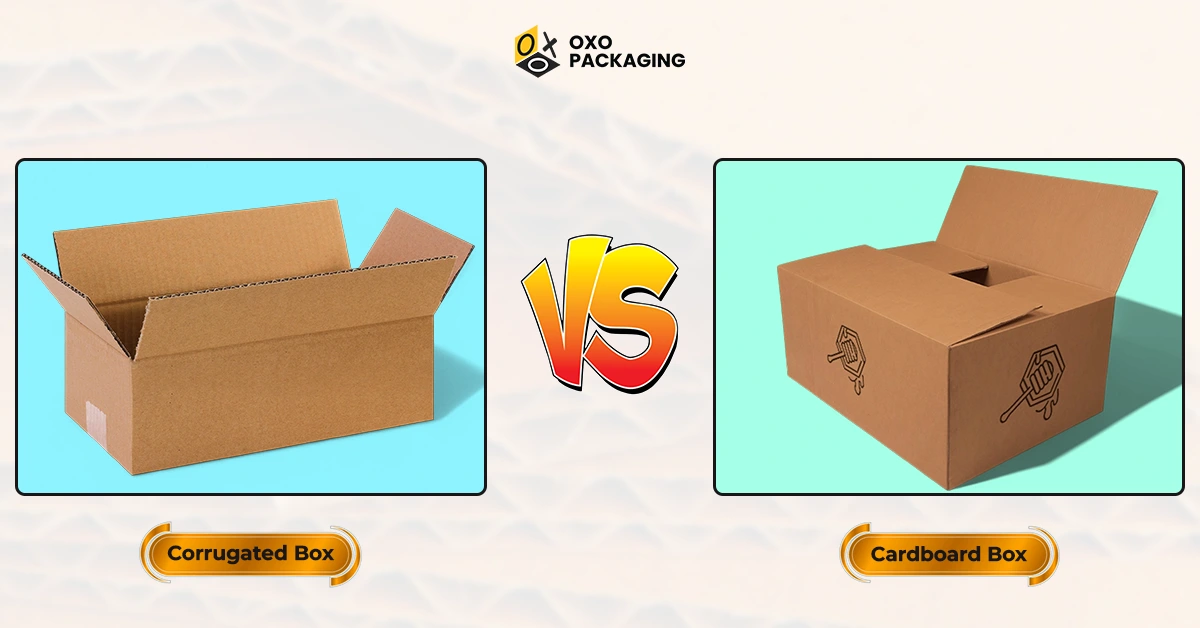

Cardboard vs. Corrugated: Key Difference

Before digging into the details of types of corrugated boxes, know the difference between corrugated cardboard and cardboard. The standard thicker paper made from paper fibers is called hard cardboard. It is often called card stock. Therefore, some people get confused between cardstock and cardboard.

On the other hand, corrugated cardboard is made by joining card stock or thick kraft paper with wavy kraft flutes. Both are sustainable, customisable, and functional. Cardboard or card stock is used to create packaging for lightweight products. And corrugated boxes are made for heavier and larger products. Corrugated boxes are more expensive than cardboard boxes.

Uses of Corrugated Cardboard Boxes

Types of corrugated boxes depend on the products and industry. The primary use of corrugated boxes is to package and transport items over long distances. Their strong construction makes them ideal for shipping. However, they are used in different industries. Almost every product-based business uses corrugated boxes for branding and product shipping. The following are some major industries that use corrugated mailer boxes and large cartons for their products:

- Retail Industry

- Pharmaceutical Industry

- Apparel and Shoe Industry

- Food and Beverage Industry

- Skincare and Cosmetic Industry

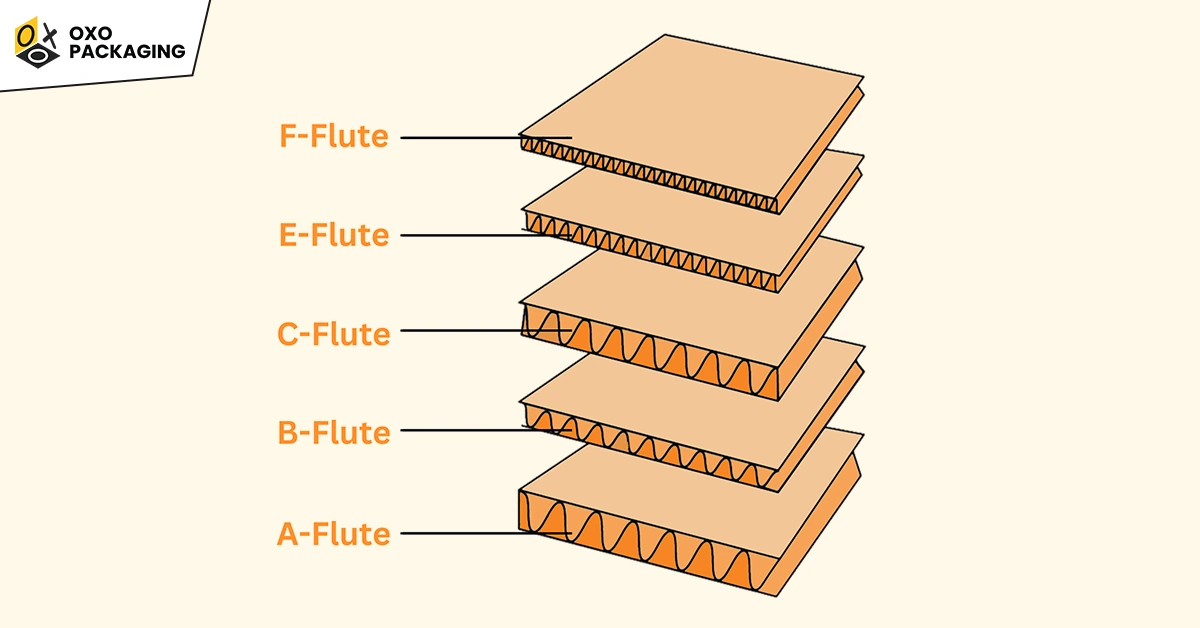

Types of Corrugated Flutes

Flutes in corrugated cardboard allow you to make a compression-resistant packaging to ensure safe product shipping. These flutes come in different thicknesses, referred to as flute grade. The following are some popular types of corrugated flutes you must know when customising different types of corrugated boxes:

A Flute

A quarter-inch-thick flute is referred to as an A flute. 1/4” is the largest size, offering superior cushioning against compression for fragile products. Corrugated boxes with A flute ensure product safety during shipping, handling, and storage.

B Flute

A 1/8” thick flute is called a b flute. It looks thinner but offers adequate support to the corrugated boxes. As a result, the flute types of corrugated boxes become puncture-resistant. The smoother surface of the B flute supports printing and customisation.

C Flute

3/16” thick flute falls under the grade C category. It is not as protective as an A flute but can be used to create different types of corrugated boxes for small retail products. C flute has average compression resistance during handling, shipping, and stacking.

E Flute

1/16” is one of the thinnest flutes used to create different types of corrugated boxes. It does not offer enough support for shipping boxes. F flute is often used for corrugated fibreboard packaging. However, it can be used to pack small dairy products, lightweight cosmetics, and small glassware.

F Flute

1/32” thick flutes are F flutes. It is even thinner than the E flute. However, it has a smooth surface, which can be printed and customised. The use of the F flute may vary from region to region. For example, F flutes are used to create clamshell boxes for fast food in the USA. But the F flute is a standard grade used to create corrugated boxes for retail products in the European market.

Styles of Corrugated Packaging Boxes

The styles of fluted cardboard boxes depend on the uses and types of products. Some popular styles of different types of corrugated boxes are as follows:

- Full Slotted Box

- Regular Slotted Box

- Slider corrugated boxes

- Tuck top corrugated boxes

- Half Slotted Container (HSC Box)

- Thick cardboard RETT mailer boxes

- Corrugated boxes with a detachable lid

Pros and Cons of Corrugated Boxes

Have a look at the pros and cons of corrugated boxes before you get them customised for your products:

Advantages of Corrugated Boxes

The following are some benefits of corrugated boxes, which help you confidently invest in these boxes:

- Sustainable and reusable

- Printable and customisable

- Most durable paper packaging

- Smoother surface than chipboard

- Good for branding and promotion

Disadvantages of Corrugated Boxes

Also, consider a few disadvantages of corrugated boxes mentioned below:

- Heavier

- Costly

- Complex manufacturing process

Conclusion!

Every product-based brand must invest in perfectly custom corrugated packaging because it offers optimum protection while improving brand awareness. Exploring the different types of corrugated box packaging helps you choose the one that aligns with your products’ packaging needs and brand personality. Find a reliable custom packaging company to customize protective and branded corrugated shipping boxes!

Feel free to contact us if you have any questions. We would love to address your queries!