The packaging you choose for your products can make or break your brand image. Consider chipboard vs. corrugated cardboard when choosing product packaging for your brand because both are popular for many reasons. You should ensure the customizability of packaging material and its structural integrity.

The more sturdy material results in packaging, which offers optimum product protection during shipping, storage, and handling. Both chipboard and corrugated cardboard are known for their versatility, sturdiness, and practicality. Read this blog to understand the key difference between chipboard and corrugated cardboard for packaging. Continue reading!

Overview of Chipboard

Before digging into the details of chipboard vs. corrugated cardboard boxes, understand what chipboard packaging is. One of the misconceptions about chipboard is that people sometimes relate it to wood, as its name implies. Chipboard is made from recycled paper instead of wood.

Different quantities of recycled paper are used to create dense chipboard. The quantity of paper depends on your needs. These papers are layered first and then pressed together to form various thicknesses of the chipboard.

Chipboard is made using multiple pressed layers of recycled paper. Therefore, it is not easy to break or bend. Its rigidity makes it ideal to ensure superior protection for fragile products. Chipboards can be used for DIY projects using die-cut technology. Likewise, chipboard works as enveloping stiffeners for safe shipping of important paper-based projects.

Overview of Corrugated Cardboard

When someone refers to a cardboard box, referring to a box made from corrugated cardboard. What is corrugated cardboard? It is a sturdy material made from multiple layers of cardstock, kraft paper, and kraft flutes. A corrugated machine is used to make wavy kraft flutes, which are used between layers of cardstock. The best thing about corrugated cardboard is that it can be customised to your desired thickness. Corrugated cardboard boxes are used to ship bulk, heavier, and large items to long distances. Mailer boxes are also made from corrugated cardboard for secure retail product shipping.

Chipboard vs. Corrugated Cardboard Difference

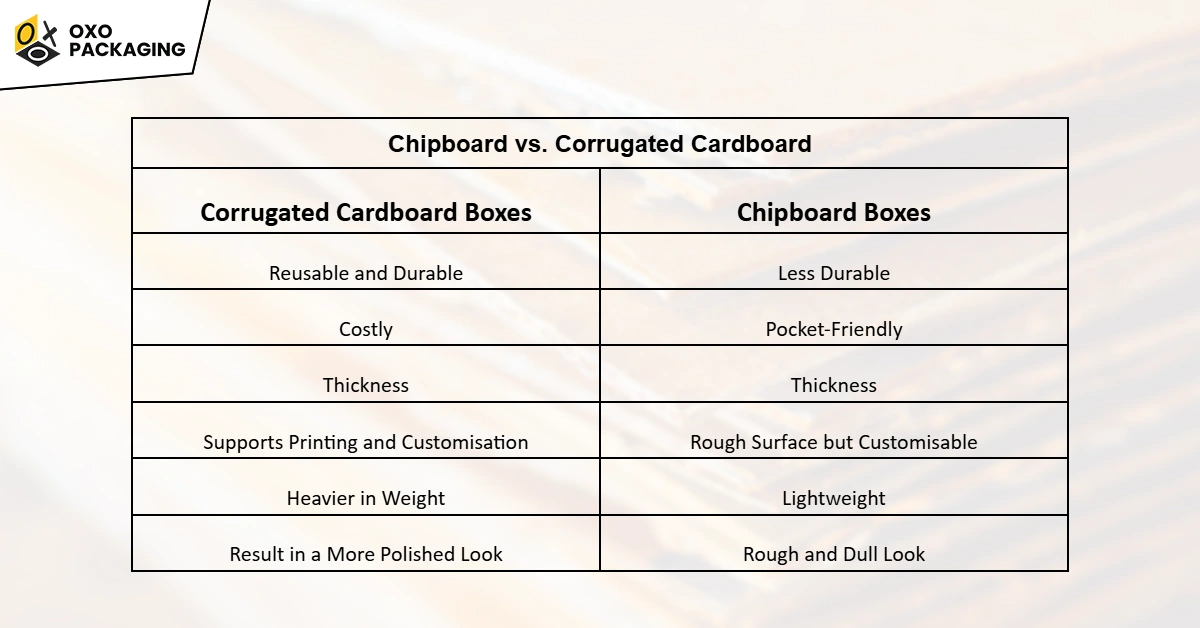

Have a look at the table mentioning some major key differences between chipboard vs. corrugated cardboard packaging:

Let’s explain every key difference in detail for your better understanding:

-

Strength

Corrugated cardboard boxes are more durable than chipboard boxes because they are sturdier. Chipboard boxes contain pressed layers of recycled paper, resulting in rough and dull surfaces. However, corrugated cardboard boxes require a thorough manufacturing process, resulting in a sleek and polished look.

-

Cost

One of the major concerns of every business owner is cost. Corrugated cardboard boxes require more material and manufacturing costs than chipboard. Therefore, corrugated boxes are more expensive than chipboard boxes. Chipboard is pocket-friendly and can be used for small products.

-

Customisation

Corrugated cardboard boxes are more customisable and printable than chipboard boxes. Chipboard has a raw and rough surface, resulting in a dull appeal even after customisation. However, you can use a chipboard as a base and get it covered with high-end materials like leather, linen, and thick paper to get a professional look.

-

Weight

Corrugated cardboard packaging boxes are heavier than chipboard boxes. Therefore, you bear more shipping costs when using corrugated cardboard boxes. On the other hand, using chipboard boxes for small and lightweight product shipping results in reduced shipping costs.

-

Uses

The chipboard packaging is not as versatile as corrugated boxes. You can ship small to lightweight products in chipboard boxes, but these boxes can not be used for shipping heavier and bulkier products. However, corrugated boxes are versatile and can be used for small to large and heavier. ones

-

Thickness

Both corrugated and chipboard boxes can be customised with your preferred thickness. However, corrugated boxes are more flexible and when customised with higher thickness, result in a professional outlook. Chipboard boxes are thinner than corrugated boxes.

-

Branding

Keep in mind branding when understanding chipboard vs. corrugated cardboard boxes. The more excellent the material surface results in more branding opportunities. Corrugated boxes are best for branding as they have an excellent surface. You can use corrugated shipping boxes with logos to boost your branding.

Factors to Consider When Choosing the Right Material

Confused about choosing materials while understanding chipboard vs. corrugated cardboard boxes? Don’t worry! We have discussed the following important factors you must consider when choosing the right material between chipboard and corrugated cardboard for packaging:

Know Your Product

Understanding your products’ nature is foremost when choosing the right materials. If you are detailing small and lightweight to medium-weight products, go with the chipboard. And if your products are heavier and larger, corrugated cardboard should be your first choice. Moving and shipping brands mostly use corrugated cardboard boxes because they need to ensure the safety of products during shipping.

Understand Customers’ Preferences

Know your brand persona and get the material customised accordingly. For example, if you have a sophisticated personality, you should pick corrugated cardboard because it supports customisation better than chipboard. If you have a rugged personality, go with a chipboard and customise it accordingly.

Be on Budget

Never put all your eggs in one basket when investing in product packaging. Corrugated cardboard is expensive than chipboard but it is worth the money because it is reusable. However, chipboard is cost-effective, and you must consider it for your retail product packaging.

Uses and Types of Chipboard Packaging

Chipboards can be categorised into brown and white chipboards to create packaging. You can use chipboard packaging for various purposes as follows:

Sheets made from chipboard are used as mailer stiffeners to ensure the safe shipping of documents that need to be shipped unfolded.

White chipboard is used to create cosmetic packaging and ensure your customers receive products in pristine condition with enhanced presentation.

Gourmet items are securely packed in white chipboard boxes for enhanced visual appeal and added protection.

Brown chipboard is used to create small to medium-sized cartons and boxes for shipping, storage, and display.

Chipboard sheets can be used as dividers in large corrugated boxes to ensure the safety of fragile items.

Notepads, notebooks, and journals are made using chipboard sheets as a base and then covered with leather and high-end paper.

Household products, for example, small mirrors, are made using chipboard sheets as a support on the backside of their frame.

Large chipboard sheets are used behind the large photo frame for support.

Uses and Types of Corrugated Cardboard Packaging

Corrugated cardboard has different types depending on the thickness, such as single-wall, double-wall, or triple-wall corrugated cardboard sheets. Likewise, the use of corrugated cardboard packaging varies depending on the products and thickness of the boxes.

Corrugated cartons are mostly used for shipping larger and bulkier items like electronics, household, and appliances.

Cardboard corrugated boxes are also used for storage purposes in warehouses and homes to ensure secure long-term storage.

The food industry extensively uses corrugated cardboard boxes for takeaway and delivery. For example, corrugated pizza boxes are made to ensure secure pizza delivery, ensuring the toppings stay intact.

Stationary product packaging like file storage cartons are made from corrugated cardboard. Corrugated cardboard mailer boxes are ideal for shipping retail products like shoes, clothes, cosmetics, and household items.

Advantages and Disadvantages of Chipboard Boxes

Chipboard boxes have some boons and some bane, like any other thing. Below are a few pros and cons you must consider before choosing the one while analysing chipboard vs. corrugated cardboard:

-

Advantages of Chipboard Packaging Boxes

Chipboard boxes are cost-effective and lightweight. They are functional and aesthetically pleasing. Chipboard packaging boxes offer adequate protection to products. They can be customised using high-end materials as a cover to create premium packaging like leather-covered rigid watch boxes. Chipboards require less complex methods and manufacturing costs to create.

-

Disadvantages of Chipboard Packaging Boxes

Chipboard boxes are not as versatile as corrugated boxes. Because their use is limited to lightweight to moderate weight and small to medium-sized products. They are less durable, and do not support the shipping of larger products. Chipboard packaging has a rough surface.

Pros and Cons of Corrugated Cardboard Boxes

Let’s discuss the pros and cons of corrugated cardboard boxes for your better understanding of chipboard vs. corrugated cardboard:

-

Pros of Corrugated Cardboard Packaging Boxes

No other packaging is as reliable as corrugated cardboard for shipping larger and heavier items. Corrugated cardboard boxes offer value for money. The reusability of corrugated cardboard allows customers to use the cartons for other purposes. Corrugated cardboard boxes are customisable, resulting in more possibilities for branding. They are sustainable, helping you build an ethical brand image.

-

Cons of Corrugated Cardboard Packaging Boxes

The heavier weight of corrugated cardboard boxes causes higher shipping costs. Secondly, corrugated cardboard boxes are costly due to more raw materials and complex manufacturing processes.

Chipboard vs. Corrugated Cardboard: What to Choose?

Choose the one that aligns with your products’ packaging needs and brand personality. You can choose the right packaging considering the uses, types, and benefits of corrugated and chipboard packaging while exploring chipboard vs. corrugated cardboard.

Still, have questions about chipboard vs. corrugated cardboard? Feel free to contact us. We would love to answer any questions!