Explore the Art & Science Behind Rigid Box Manufacturing!

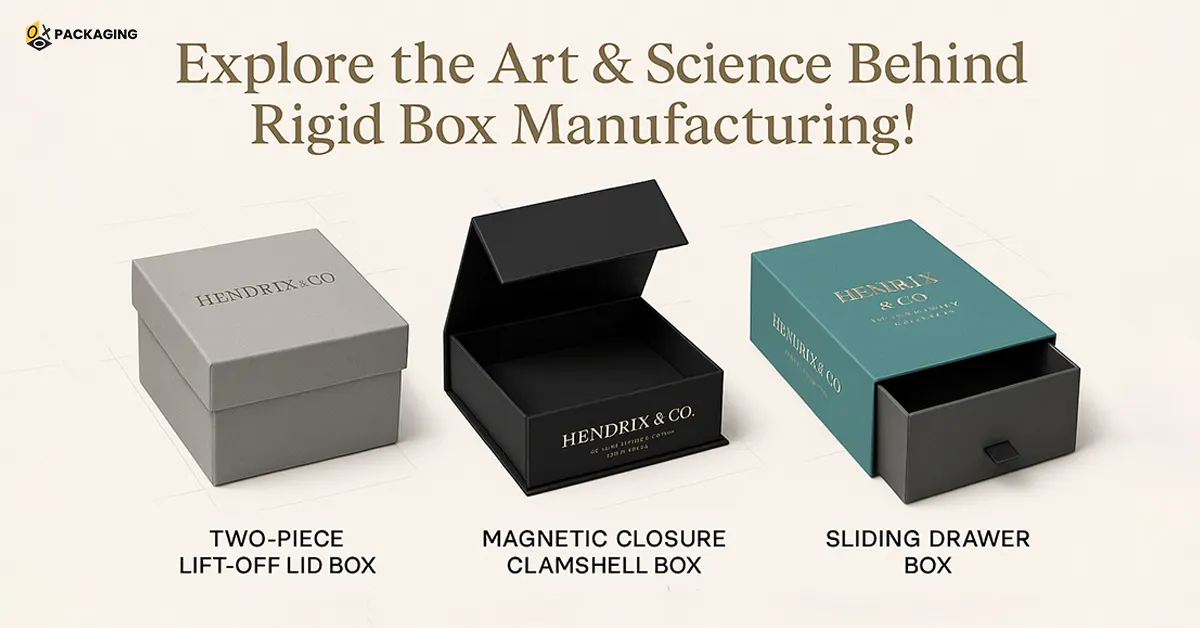

Packaging has evolved into much more than just a protective layer for products. The box itself tells a story about quality, trust, and exclusivity in the modern competitive market. Rigid boxes stand out as the symbol of luxury among all premium packaging solutions.

They are sturdy, stylish, and perfectly customised to elevate the perceived value of any product inside. But what actually goes into making these elegant packaging pieces? Let’s take a deep dive into the art and science of rigid box manufacturing, from materials to finishing touches.

The Importance of Luxury Rigid Boxes

When customers pick up a product, the first interaction is often with its packaging. Luxury brands understand this well. That is why they rely heavily on rigid boxes. Unlike folding cartons, these boxes are made with a thicker board that gives them durability, strength, and a premium feel.

A rigid box goes beyond mere protection of a product; it enhances the unboxing experience for recipients. Imagine opening a phone box, a high-end perfume, or a luxury watch. The slow reveal, the strudiness of the lid, and the fine textures instantly create anticipation and excitement. This is why luxury packaging is no longer “nice-to-have” but a core part of brand identity and consumer psychology.

Rigistock as a Packaging Material

At the heart of every rigid box lies rigidstock. Put simply, a rigid stock is a strong, paper-based material that serves as the backbone of the structure. It is thicker and denser compared to regular paperboard, making it ideal for retaining shape under pressure. The benefits of using rigidstock include:

- Durability: Can handle heavy products without collapsing.

- Smoothness: Provides a clean surface for wrapping and printing.

- Eco-friendliness: Most rigid stock is recyclable, which aligns with sustainability goals.

This material ensures the box not only looks good but also performs functionally while protecting the product during shipping and handling.

Core Material

The core material is essentially the skeleton of the rigid box. Typically made from greyboard or chipboard, it determines the strudiness of the box. The thickness of this board varies depending on the product being packaged. For example, luxury electronics need thicker cores than lightweight accessories.

Manufacturers cut and score the core material into precise panels. These panels are then assembled into the base and lid, which provide a strong foundation before wrapping and finishing are applied. Without the right core material, the entire structure of the rigid box would collapse.

Wrapping Material

The beauty of rigid boxes comes from their wrapping material. While the core material provides structure, the wrapping paper provides elegance. The wrapping layer is usually made of fabric, specialty paper, or even faux leather.

Luxury brands often choose wrapping materials that align with their identity. For example, they choose matte or glossy papers for modern minimalism. And textured papers for a sophisticated and elegant image, while fabric wraps for exclusivity.

However, the personalised wrapping paper is applied carefully while ensuring seamless edges and crisp folds. This is where craftsmanship plays a huge role, as even a minor wrinkle can affect the luxury appeal of a rigid box.

Essential Adhesives

Adhesives are the silent heroes of rigid box manufacturing. They may not be visible, but they hold the entire packaging together. Specialised glues are used to bond the core material panels and secure the wrapping material.

The type of adhesive depends on the material combination; paper-to-board or fabric-to-board may need different formulations. Good adhesives ensure that the wrapping doesn’t peel over time and that the box maintains its shape even with frequent handling.

Manufacturing Process for Rigid Packaging Boxes

Creating luxury rigid boxes involves precision, skill, and attention to detail. Their manufacturing process can be broken down into three major steps:

Material Preparation

The journey begins with preparing the core board and wrapping sheets. Boards are cut to exact dimensions using die-cutting machines. However, wrapping papers are trimmed and sometimes printed with brand designs, textures, or foils. Accuracy at this stage ensures smooth assembly later.

Box Forming & Wrapping

In the second step, cut boards are assembled into box structures either manually or with semi-automatic machinery. Afterward, corners are glued and folded to give the box its shape. Next, wrapping sheets are carefully laminated onto the box, which ensures smooth coverage with bubbles or creases.

Tailored Finishing

This is where magic happens for rigid boxes. Finishing processes like embossing, debossing, foil stamping, spot UV, and lamination elevate the box from functional to luxurious. The premium finishes add not just beauty but also tactile richness, making the unboxing feel “indulgent.”

Customisation Choices for Luxury Rigid Box Packaging

Rigid boxes are highly versatile, which gives brands endless customisation possibilities to stand out in a competitive market. Consider these fantastic options to customise your boxes in the best way:

-

Tailored Shapes & Sizes

From classic square and rectangular boxes to innovative hexagonal or book-style designs, rigid boxes can be crafted into almost any shape. Custom sizes ensure your products fit snugly while enhancing safety and aesthetics.

-

High-End Prints

Brands can incorporate high-resolution graphics, metallic foils, holograms, and textured prints on wrapping to appeal to luxury-conscious customers. Printing technology allows even the most intricate designs to appear crisp and vibrant.

-

Exclusive Inserts

Premium rigid boxes often come with inserts that are made from foam, molded pulp, or velvet lining to hold products securely in place. Inserts not only protect but also add sophistication by ensuring a perfect presentation when the box is opened.

Industries Where Rigid Boxes Can Be Used

The perfect blend of premium aesthetics, durability, and eco-friendliness makes rigid boxes a popular choice across many industries. In each of these industries, rigid boxes serve the dual purpose of protecting valuable products and strengthening the premium positioning of your brand.

Luxury Fashion & Accessories

The firm, non-collapsible structure of rigid boxes keeps delicate and expensive items like jewelry, perfumes, and watches safe from damage during shipping and handling. High-end finishes and a luxurious presentation on these boxes make your products stand out, enhancing brand credibility and positioning the brand as high-end.

Cosmetics & Beauty

Rigid boxes exude a luxurious and high-end impression, making beauty products appear more valuable and enticing customers to make a purchase. Their sturdy, durable construction safeguards delicate cosmetic products from moisture, heat, dust, and physical damage, ensuring they reach consumers in pristine condition.

Electronics

Rigid packaging boxes significantly reduce the risk of damage to sensitive electronic components during shipping and handling. Their sturdy, upscale appearance elevates the perceived value of electronics, signaling quality and luxury to customers.

Food & Beverages

By keeping food sealed and safe from contaminants, rigid packaging extends the product's shelf life and preserves its value for consumers. The rigid structure of these boxes protects food from external factors like moisture, dust, and heat, preventing spoilage and maintaining freshness.

Corporate & Gift Packaging

Rigid boxes exude a professional and luxurious image, reflecting respect for corporate partners and elevating the brand's perceived value. Their smooth and thick surface is feasible for high-quality printing of logos and marketing messages, which increases brand recognition.

Wrap Up!

Rigid box manufacturing is an intricate balance of precision and artistic craftsmanship. From the strength of rigid stock and the strudiness of core material to the beauty of wrapping and customisation, every detail is carefully designed to create packaging that speaks volumes of luxury.

Investing in rigid packaging is more than just choosing a box; it is about shaping perception, building trust, and boosting customer loyalty for brands. Rigid boxes continue to be the “gold standard” for premium packaging in a marketplace where first impressions matter.

A rigid packaging box is famous for its hard and robust appearance. It is made of easily customisable yet thick and durable materials. On the other hand, folding boxes are famous for their flexibility. Such boxes are not as robust as rigid ones, yet provide convenience in opening and closing, along with saving your budget, as they are highly cost-efficient.

Rigid boxes come with endless benefits, making them ideal for luxury product packaging. You can pack multiple types of products like jewellery, cosmetic products, watches, and more in these boxes. The robust construction of these boxes protects the items packed inside them. Also, these boxes glorify your brand’s appeal with a persuasive and high-end appearance.

The thickness of rigid packaging boxes depends on your specific requirements. The minimum thickness of these boxes starts from 500 GSM. However, this thick box is far thinner than you mostly see. Standard thickness of rigid boxes ranges from 100 GSM to 1800 GSM.