Packaging is an important part of every product-based business, whether it is a B2B or B2C set up. B2B businesses often face challenges in optimising their operations, reducing labor costs, and improving customer satisfaction. One way for B2B companies to boost their business operations is packaging automation, which helps them streamline their packaging operations.

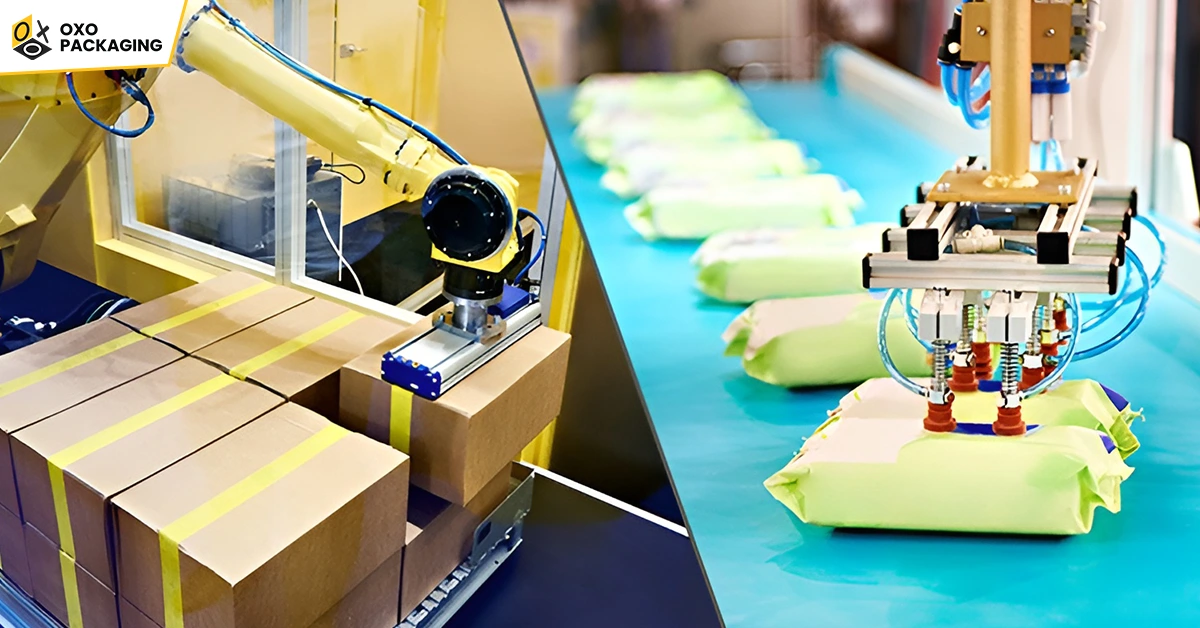

The use of advanced packaging technology helps businesses improve efficiency while reducing costs. Packaging automation is the process of packing and sealing products using advanced machinery to minimise errors and manual labor costs. Read this blog to know how packaging automation is benefiting b2b businesses!

What is Packaging Automation?

Packaging automation is referred to as automated packaging solutions, which help b2b companies streamline their product packaging and sealing operations. Advanced machinery is used to perform the product packing, sealing, labeling, and coding tasks to make the process efficient.

An impeccable packaging automation system allows b2b businesses to save energy, which they can use to focus on producing quality products or launching new products.

The E-Commerce industry is rapidly expanding and is one of the reasons for the use of packaging automation. The efficiency and effectiveness of packaging automation machines make them a desirable investment for b2b companies that need to handle high-volume product packages quickly. In short, packaging automation integrates high-speed equipment that can create, pack, fold, and seal your product without wasting time.

Types of Packaging Automation Machines

Business owners often look for cost-effective ways of doing business. However, they tend to invest in solutions that offer them long-term cost and time efficiency with zero error, like packaging automations. The complex supply chain operations can be handled easily when done using automated machines. B2B companies such as electronics, moving and shipping, food manufacturers, construction, printing, or packaging need to consider the following types of automation packaging:

Auto Beggers Machines

Bagging machines are automated devices that fill pre-made pouches with products. After product filling, the machine cuts the extra part of the pouch and seals the package. Most perishable powder-based and semi-liquid products are generally packed in Mylar pouches using auto bagger machines. Begging machines significantly increase packaging speed and efficiency.

HFFS Machines

Horizontal Form Fill Seal, aka HFFS, machines form, fill, and seal flexible pouches horizontally. HFFS automated machines are commonly used in the food industry for packing and sealing single-serving solid products like biscuits, candies, chocolate, and snack bars. These machines are versatile and can be used for packing and sealing a variety of different products like granules, powders, and liquids in high volume.

Filling Machines

Filling machines are also known as automated fillers, which are used to fill the product in pre-made packaging like bottles, tubes, and bags. Manual product filling takes a lot of time and labor costs. Using filling machines for packing products like agricultural fertilizer, powdered materials used for construction, food, cleaning products, and pharmaceuticals can save you time and money. Filler machines come in various designs, including semi-automatic tabletop models and automatic multi-head machines to fill different products in pre-made packaging.

Labeling Machines

Automated labeling machines work best in high-volume production settings. These machines can be integrated into the conveyor systems to ensure efficient and impeccable product labeling. Products automatically move under the machine, and the machine quickly prints the label on them. Depending on the preference, labels are applied to the products with different methods, like arms, rollers, or air blasts.B2b companies like manufacturing or logistics can take advantage of labeling machines to improve cost-effectiveness.

Palletizers

Storing bulk products and taking them from one place to another requires a lot of labor costs and energy. Palletizers make it easier for b2b companies to store their products quickly and efficiently while reducing labor costs. A palletizer is also known as a case picker. It automatically stacks boxes or heavy products onto pallets. Consequently, this process makes it easier to transport and store goods in industrial or warehouse settings.

Shrink Wrapping Film Machines

As the name suggests, shrink wrapping machines are used to shrink plastic film tightly around products with the help of heat. Most retail products go through shrink wrapping machines for enhanced sealing, visual appeal, and a professional finish. As compared to traditional packaging methods, shrink-wrapping automated machines reduce labor costs and material waste.

Thermoformer

An automated thermoformer machine is used to create different shapes and sizes of plastic sheets to pack and seal various products. Thermoformer is used to create plastic trays and blister packs, which are often used in the food and pharmaceutical industries. The thermoformer machine applies heat and pressure to the plastic sheet to create different types of packs.

Tray Sealing Machines

Tray sealing machines are often used in the food industry. Food items are placed on the trays, and those trays go through a plastic film sealing process. Tray sealing machines are used to seal those products that need to be visible for customers to see, such as meat.

Cartoners

As the name suggests, automated cartoners are used to fill and seal large cartons for storing products in bulk. B2B companies like the construction industry can pack and store their products in large cartons using cartoners. These machines insert products into the cartons and seal the carton ends with different closing mechanisms such as tuck-in, folding, or adhesive application.

Stick Pack Machines

An excellent example of packaging automation is stick pack machines. The global stick packaging market is expected to grow to around USD 826.03 million by 2034 due to its extensive use in the food and pharmaceutical industry. These automated machines create stick-like packages ideal for single-serve products such as coffee, sugar, or pharmaceutical powders. Stick packaging is extensively used in the pharmaceutical and food industry for making single-serving packages that are used in hotels and restaurants.

Benefits of Packaging Automation for B2B Companies

B2b companies, whether it is a construction or agricultural companies, can enjoy the following benefits with packaging automation:

- Minimise Errors

- Reduce Labor Cost

- Improve Efficiency

- Ensure Product Safety

- Reduce Packaging Waste

- Enhance Product Scalability

Feel free to contact us if you still have any questions. We would love to answer your queries!