Kraft Paper vs Cardboard: Which Eco-friendly Packaging Brands Should Choose!

2026-01-16 12:59:27

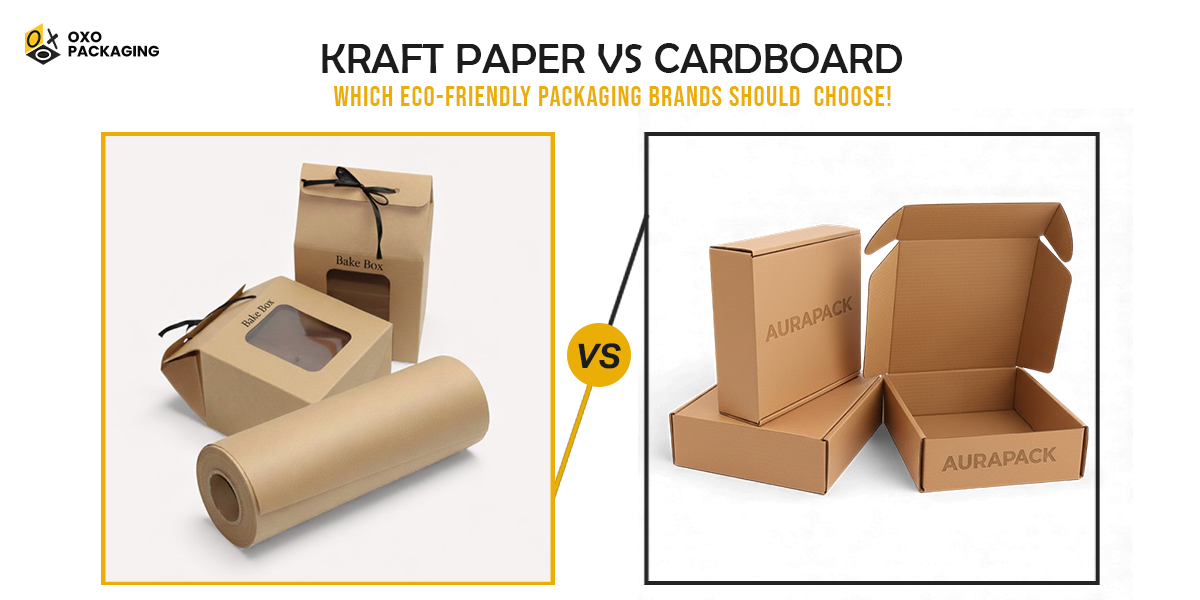

Kraft paper and cardboard are both honoured heroes of packaging, both in terms of durability and cost-effectiveness. However, they both exhibit distinctive traits, features, and may vary at the surface level as well when custom printing and coating are applied, which can also hurt their sustainability.

Therefore, which materials remain more sustainable even after customisation? Let’s delve into the origins of both materials, their personality traits, and determine which is the more eco-friendly option for the brand to choose, thereby demonstrating a soft spot for minimising ecological footprint.

Roots of Kraft Paper

The origin of kraft paper dates back to the time in the 1880s when German chemist Carl F. Dahl invented the process where wood is ‘pulped’ first, then the chemicals like sodium sulfate and caustic soda are combined to make a strong paper. And that’s why it is named “Kraft”, derived from the German language, which means “strength”.

It’s real clear that Kraft paper boxes are crafted from unbleached process, making it one of the most biodegradable materials in the packaging world. The study indicates that the market for kraft paper was worth $17 million as of 2020, growing at an average rate of 3.5%. This means that by 2028, the estimated Kraft paper packaging is expected to be $22.38 billion.

Crazy right? Well, aside from the eco-friendly nature of the kraft exhibit, its classic rustic texture lends undeniable charm and minimalist branded packaging, which many brands are opting for, to amplify market trends and exciting eco-conscious consumers, resulting in high-converting sales.

Roots of Cardboard Boxes

Let’s not forget the most reliable and shipping expert “cardboard Boxes”, which you’ll see in your storage, bunk and trunks. In China, during the Han Dynasty, the first paper made of cardboard was invented, and its primary uses were for artwork and writing.

The first precursors to cardboard were created by layering sheets of paper together for added strength. This technique evolved into paperboard, creating a stiffer and thicker version of paper, which has now become the widely used material in the packaging of goods, ranging from small boxes to containers.

Contrast Kraft & Cardboard in Terms of What Makes Them Less Eco-friendly & Recyclable

Are cardboard boxes sustainable? Yes! Cardboard boxes made from renewable resources, like wood, can be replenished through sustainable forestry practices, thereby reducing the need for virgin materials. However, when the multi-layer and additional branding materials like adhesives, coatings or laminations are applied in the construction of solid & premium packaging, they often hinder its biodegradability and complicate the recycling process.

On the other hand, kraft paper sustainability is tougher than cardboard, even when multi-layering is applied, and additional branding elements such as adhesives, coatings and laminations do not significantly impact its biodegradability, recyclability, and sustainability.

Why? Due to its more efficient and self-sustaining production process, which includes the source of its fibres, it recovers and reuses about 90% of the chemicals involved in the pulping process, which significantly minimises waste and the need for fresh chemical inputs.

Comparison in Terms of Environmental Impact

Learn which one has fewer harmful substances on Earth:

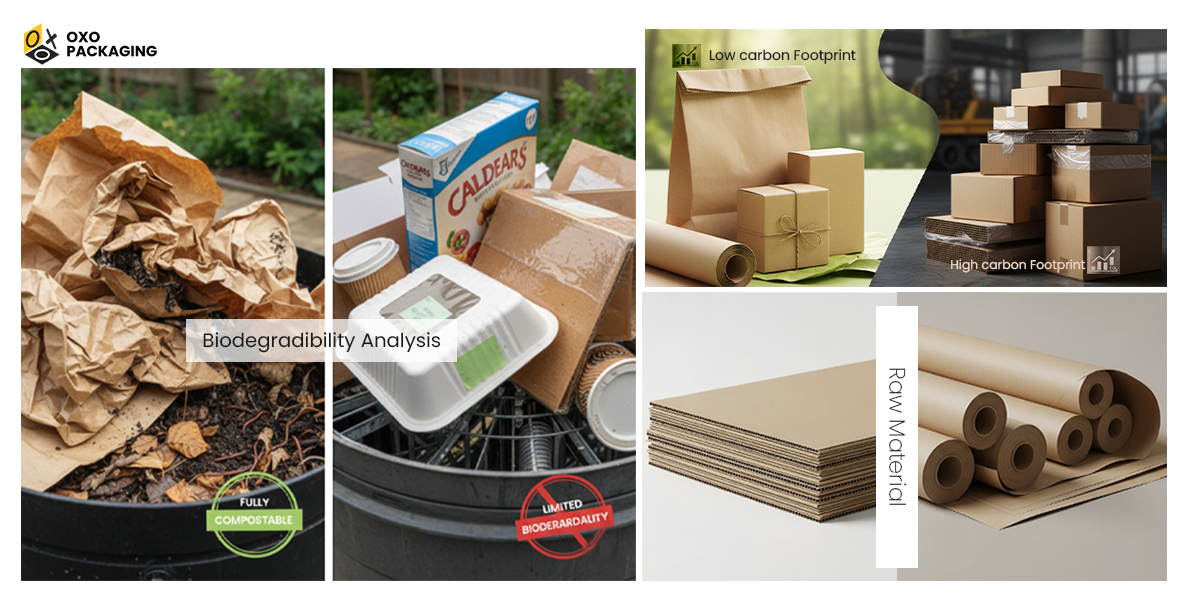

Usage Of Raw Materials

As discussed earlier, in the manufacturing process of kraft paper, only a few raw materials & chemicals are used, primarily from virgin softwood pulp, often sourced from sustainably managed forests, which gives kraft paper real strength, durability, and earthy aesthetic texture.

In comparison to kraft paper, cardboard is a mixture of multiple raw materials, including virgin pulp and recycled fibres for inner fluting layers, and outer layers that are also bleached to achieve a high-quality and smooth printing, which hinders the biodegradability and sustainability.

Energy Consumption Analysis

In terms of energy consumption, Kraft wins! As Kraft paper requires fewer processing steps, less chemical usage, and the reuse of by-products for energy, it significantly reduces energy consumption compared to cardboard production. As a result, Kraft production uses 20-40% less water and 30-50% less energy.

Carbon Footprint Analysis

Due to the rising demand from consumers for eco-friendly and biodegradable packaging, kraft fulfils the needs, as it is fully recyclable, biodegradable, and has a significantly lower carbon footprint than cardboard, due to its simpler, less energy-intensive process, which saves energy and landfill space.

Cardboard, however, has a high carbon footprint. The industrial revolution’s advancements in cardboard manufacturing, including the addition of multi-layering, corrugated flutes to increase material thickness, and the addition of coating and lamination, make the recycling process more complicated, also affecting sustainability.

Process of Biodegradability

The lifespan of both cardboard and kraft paper is approximately 2-3 months, indicating that both materials are biodegradable. Bear in mind that this process may vary with the coating applications. While Kraft with different coating and layering, is fully compostable and decomposes both in home and industrial settings.

However, the biodegradability of cardboard is compromised when coating, adhesives and lamination are applied, which significantly hinders the process and sometimes requires industrial composting to achieve biodegradability.

Comparing Kraft & Cardboard in Terms of Cost-Effectiveness & Durability

Durability: Both kraft and cardboard are highly durable boxes; they both can be manufactured in multilayered form with inserts to enhance the cushioning effect, providing excellent security for fragile items.

Cost-effectiveness: Kraft paper is often considered the most cost-effective solution, not only in terms of light weight and cost-saving shipping, but also in terms of manufacturing and customisation. But why? No brainer required, Kraft has the natural, earthy textured aura that gives a sense of luxury and elegant packaging that works perfectly in influencing customers' buying decisions.

Cardboard is your good-to-go solution for large-scale operations. These boxes require a multi-layering process, and to add the essence of branding, you will need to add adhesives and coating, which will result in more expensive manufacturing. However, these boxes save the cost of additional protection measures that will ultimately result in lower costs.

Final Thoughts

Now you know the advantages and disadvantages of both materials. So if your agenda is eco-branding and joining the upcoming trends in the packaging industry, and creating a soft spot in the hearts of eco-conscious consumers, kraft paper is standing by for you.

While we understand the benefits, it’s essential to know that before investing in Kraft, you can customise this packaging with your branding elements to reinforce premium branding. If you want to customise kraft packaging wholesale, OXO Packaging offers discounts and free design support too.

Yes, the Kraft paper is highly eco-friendly as it is made from wood pulp and is unbleached. Kraft paper is highly recyclable, reusable, and can be frequently recycled over a plenty of times

Kraft is made from wood pulp and is usually a single paperboard sheet that is sufficiently thick. Cardboard can be made of single or multiple layers of chipboard. Cardboard is highly recyclable and can be derived from wood pulp or from fully recycled post-consumer content.