Role of Finishes in Elevating Your Ordinary Packaging to a Premium Look

2025-12-15 12:28:34

Businesses that stand out in a competitive market often prefer to invest in packaging. The reason is that studies suggest premium packaging design influences the purchase decisions of around 72% Americans.

Their concern is not just a durable material, but also in finishes that enrich customer experience while making the business stand out on shelves. Why? What's more enjoyable for your customer is not always what’s inside, but the real joy of unboxing that offers a premium feel.

Also, if you want your simple boxes to leave a lasting impression on customers’ hearts, then adding finishes to your ordinary boxes is a professional yet affordable way out.

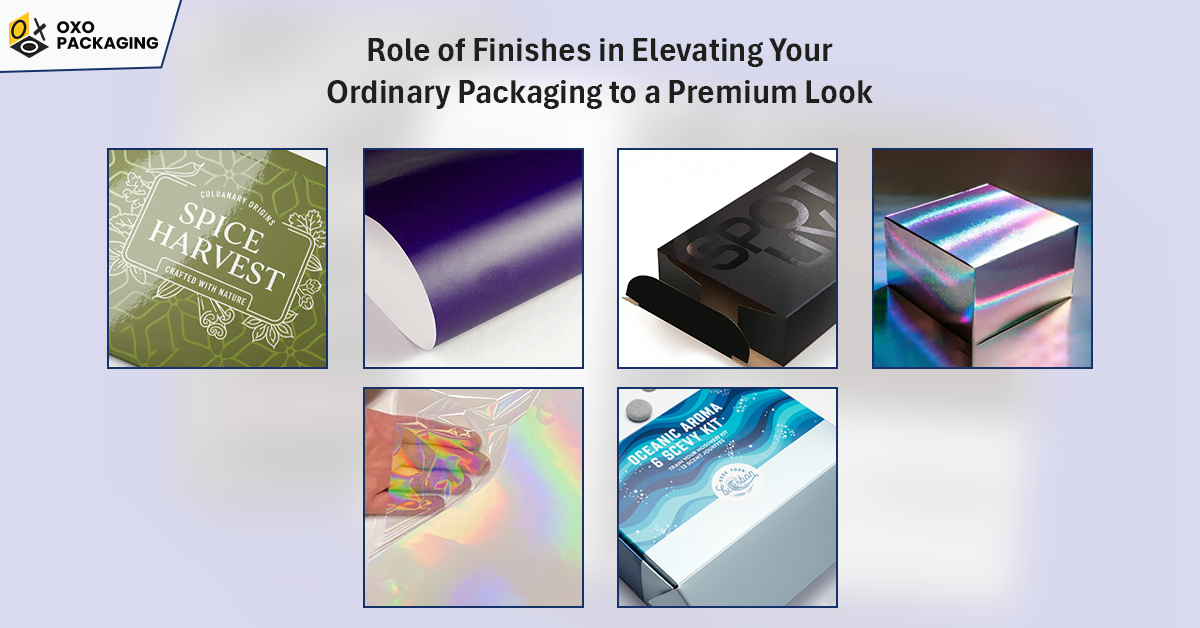

In this blog, you will learn how finishes do brand storytelling and give your products a premium look. Learn each type of finish that conveys a unique appeal. Read on!

Importance of Finishes in Business Enhancement

First impression is the last impression: yes, Packaging finishes are what your brand may be lacking. Make an informed decision, evaluate which type of finish will be suitable for your packaging.

What are Packaging Finishes?

Think of finishes as one of the essential aspects of your high-end packaging; they glorify your product in a sleek way. It is applied to the surfaces of packaging materials, like paperboard, corrugated, rigid, and pouches. Finishes ensure the fine touch of elegance and protection from scratches and general wear.

Choosing a suitable finish, like killing two birds with one stone, as finishes do the protection while enhancing packaging appeal and the customers' experience.

Types of Finishes You Must Explore

When it comes to picking one option, it becomes difficult as you have endless finishes to choose from! The following are the popular packaging finishes list to consider:

Coating Finishes:

Coating Finishes are protective and decorative layers applied to the surface of your boxes to improve appearance.

- Matte Coating: Matte coating complements the industry's aim to convey a premium, sophisticated, and natural brand identity. Popular for grabbing customers' attention with its soft touch, subtle, and modern aesthetics.

- Gloss Coating: Gloss Coating screams vibrant, eye-catching, and modern appearance. The glossy touch promises your product's appearance on shelves through a sleek and polished look.

- UV Coating: This coating not only gives a classy look, but it also serves as a safeguard to your packaging. Perfect for extending shelf life, while the high-gloss finishes protect from scratches.

- Aqueous Coating: Promote sustainability through eco-friendly finishes. It’s a water-based product that provides a subtle sheen, enhancing the overall look of the packaging.

- Soft-Touch Coating:This finish gives a luxurious touch to your packaging. It’s smooth, velvety, matte texture enriches customers' experience every time they open the product.

Lamination:

This laminating film protects printed materials on your boxes from scratches and spills while producing a shiny appearance.

Gloss Lamination: Similar to the gloss coating, but a more durable option, designed to survive the rigors of handling and transportation through its thin layer of transparent gloss plastic film on the surface.

Matte Lamination:This finish is a luxury blended with subtlety. It’s a non-reflective finish with matte lamination, ideal for industries that require low glare and resistance to fingerprints.

Soft-Touch Lamination: Primarily used by businesses that want a high-end, sophisticated, and premium look. The industries include cosmetics and jewelry.

Metallic Lamination: If you are searching for a type of finish that adds elevated shine and an instant attention grabber, metallic lamination is your answer!

Foil Stamping:

Foil stamping offers a luxurious and durable finish that enhances brand appeal, with key benefits including superior resistance to wear and increased perceived value.

Cold Stamping: It’s a more affordable option as it doesn’t use heat to stamp, just UV light to adhere the stamping. But do not underestimate its durability.

Hot Stamping: For high-end packaging and small runs, hot stamping stands out like a superhero as it provides a vibrant look, sharp details, and is highly durable.

Embossing and Debossing:

Both Finishes add professional and tactile appeal to the product and branding, with benefits including high-end highlighting of logos and important information.

Embossing: Not just an ordinary finish, but this finish creates a premium tactile experience with 3D design, increasing customer engagement while making it more resistant to wear and tear

Debossing: Enhance your brand perception with a premium, tactile, and durable impression on the product. It adds depth and sophistication without needing flashy ink.

Speciality Finishes:

These finishes can dramatically enhance the visual appeal of your boxes, creating protective layers and adding texture to boost engagement with your product.

Glitter Coating: Want your product to shine exclusively? Then choose glitter coating for boxes. This offers multiple colors, creating a dazzling effect on your packaging, making it an ideal tool for enhanced brand perception.

Sand Coating: This creates a unique, rough, textured surface that enhances grip. It is perfect for businesses that seek a tactile and durable touch.

Pearlized layer coating: This finish creates a pearlized, shimmery effect that appears like your product is glowing within.

Scented Coating: Get your customer hooked with scented coating, which infuses fragrance into the finishes that leaves an impression on your customers.

Foil VS Embossing: Which One Wins?

Stuck in the debate of which finish complements your packaging? Let's break down the loop of foil Vs embossing.

Foil Stamping:Foil stamping is a reflective finish for your packaging, so that it won’t get lost in the hyper-crowded retail shelves. The making of foil stamping is as pleasing as it looks. The process includes taking foil material and melting the foil color of your choice into the paper stock. While foil also comes in a wide range of finishes, allowing you to lessen the shine by opting for a matte finish.

Embossing: This pop-up finishes, not only looks great, but it’s a clever way to grab customers' attention. It goes perfectly with a heavier paper stock, as it enhances the visibility of graphics and text.

So, you see, both have their own pros and cons; you can choose whatever finish you want that aligns with your brand voice.

Guide to Finishes for Packaging Materials:

Now you know premium box finishes, the real challenge begins with determining which material suits which finish. Let’s solve this in seconds:

Cardboard: When it comes to cardboard, you don’t have to worry much about finishing. The reason is that such a material can support nearly all types of laminations and coatings. You can apply from gloss and matte to metallic foil and holographic finishes.

Paperboard: This packaging material is commonly used in retail businesses. Most laminations and coatings are ideal to make paperboard packaging look presentable and protected. However, immersion-based coatings won’t be the best option for this material.

Rigid: Rigid material is known for its luxurious charm in the packaging industry. Matte lamination is a popular choice for rigid boxes; however, you can opt for gloss, spot UV, embossing, and debossing as well to make them stand out even more.

Mylar: Mylar bags are typically used in food packaging and shipping. Opting for gloss and matte finishes works well with most branded mylar bags.

Where to Find Premium Packaging Finishes for Your Packaging?

You can find premium finishing from various sources, including online marketplaces and reputable packaging businesses. However, if you are looking for customization from scratch, including material, designs, shapes, and finishes, you can get in touch with OXO Packaging. You can get unlimited customisation options, excellent customer service, and hefty wholesale discounts all across Australia!