Comprehensive Insights on Rigid Box Packaging You Should Know About

2026-01-19 11:52:11

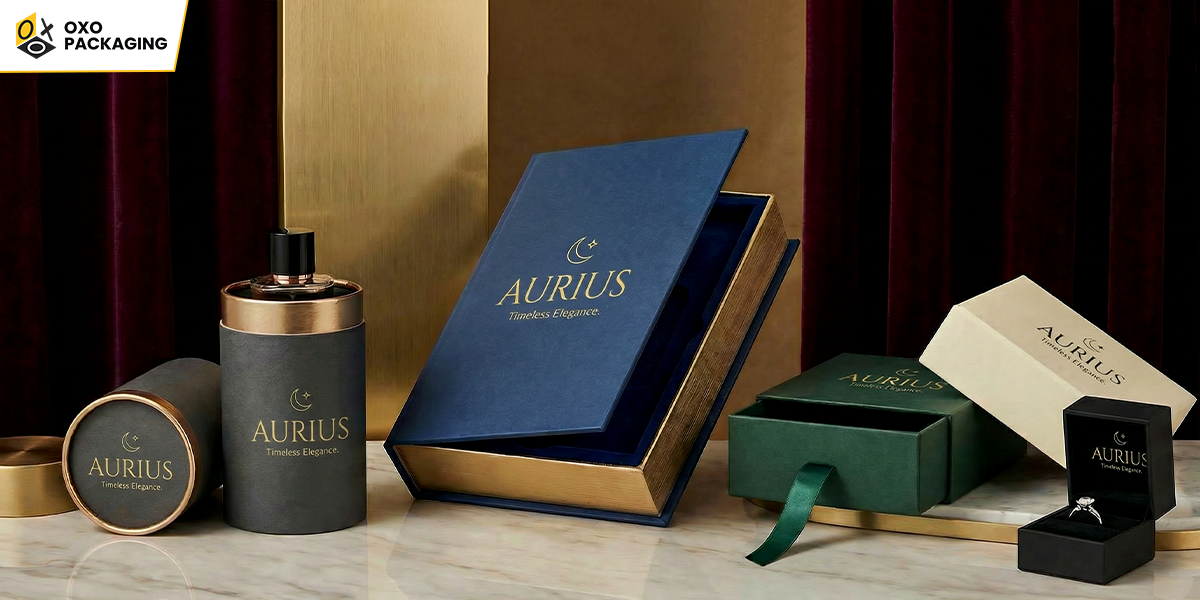

Rigid boxes are the backbone of luxury packaging. Standing as the only top choice, these are one of the exceptional packaging solutions of all time. Here in this blog post, we’ll explore its distinctive features, styles and more. So, read on to deep dive into the aspects you may not know about before.

What is a Rigid Box?

Tailored rigid boxes are the benchmark of luxury packaging that are made from thick-layered chipboard around 2-3mm. This paper-based box is very sturdy and is an ideal option whenever it comes to high-end solutions.

Also known as set-up boxes, it is the first choice for packaging of jewellery, watches, valuable gifts and more. Its outer surface is something that makes it distinctive and stands out from the rest of the packaging options. That’s why it counts a lot, as some of the most popular ones are:

- Embossing/Debossing

- Hot Foil Stamping or UV Spot

- Laminated or Matte Coatings

What Makes Custom Rigid Boxes Unique?

If you’re exploring rigid boxes for the first time, you may find it interesting to know about some similar types. Yes, we’re talking about them in detail. Yet below are some of the factors that make them distinctive from each other.

- Set up: For the rigid boxes, there’s no need to make them from scratch right before their usage. Once it’s developed in the production phase, it’s fine. While for folded and corrugated cartons, they demand assembly as they can be folded during logistics or when not in the functional state.

- Strength: The durability of rigid and corrugated packaging is at the top compared to the folding boxes. They stay in their best shape and condition for long without getting damaged or early wear & tear. While folding boxes are more susceptible to losing their form due to on & off assembly & disassembly.

- Product Protection: Keeping the pristine condition of a product is a major concern. All of the above three-mentioned boxes do their job very well in securing the items inside. For folding boxes, they must be added with inserts or dividers because its foldability may affect the product during logistics.

- Price: For rigid boxes, the cost of non-negotiable factors and brand tends to pay to get their desired quality because it’s something that makes them stand out. Yet, for the other two options, its cost heavily relies on the printing and finishes, the more you demand, the more you pay and vice versa.

- Appearance: Likewise, the rigid boxes are the core of luxury presentation. While folded and corrugated boxes also attract customers, rigid boxes are personalised uniquely.

- Reusability: Unfortunately, folding boxes have the least usage after being used once for the actual product due to their structural features. But rigid and corrugated boxes can be utilised multiple times for a range of purposes. In fact, individuals keep the rigid boxes as something special to store their belongings with full passion.

Wrapping of Rigid Boxes Packaging

There are commonly two types of rigid boxes that make both a distinctive option over each other. From the outside, there may not seem to be such a major difference because it looks the same. Yet when the box is examined from inside, that’s where the change can be spotted. Based on this, they’re divided into two categories: partial finish and full finish.

Partial Finish

First of all, in the partial finish, the wrapping onto the chipboard is complete from the exterior’s side, but from inside, it touches the edge around 1-2 inches or more. This exposes the interior side of the box material in its original appearance with no coatings at all.

Full Finish

Secondly, as the name suggests. In the partial finish, the box is coated completely from top to bottom, one side to another and beyond. There’s not a single inch that seems exposed but coated with a layer that also promotes the branding with printed logos or graphics of the brand.

Practical & Exquisite Styles for Every Packaging Need

Once the outer finish is determined, the very next phase is defining its opening/closing mechanism to develop a fully functional box. There are a lot of style options we start counting them, yet some of the common and practical ones are:

- Hinged lids in which the box’s top is attached to the upper end of the box on any side wall. The boxes that cater to this design are flip top, cigar, clamshell or even book style.

- Shoulder neck boxes, as their name suggests. There’s a flat stable base, with an inward sophisticated box that can be covered with a detachable lid to access the inside content on-the-go.

- Drawer-style boxes that open in a stylish way are the same as the actual drawers. The opening side is integrated either with a handle or a satin to easily pull the container of the box.

- Magnetic closure boxes feature a magnet on both sides, the closing lid and the box’s area where the lid settles. It’s ideal for the packaging of high-value products such as gold/diamond jewellery or luxury watches.

- Tube or rolled-edge tube packaging is a popular choice in the industry because of its cylindrical shape. These boxes are widely used by fragrance brands because their sturdiness protects the delicate glass bottles from getting damaged at any phase.

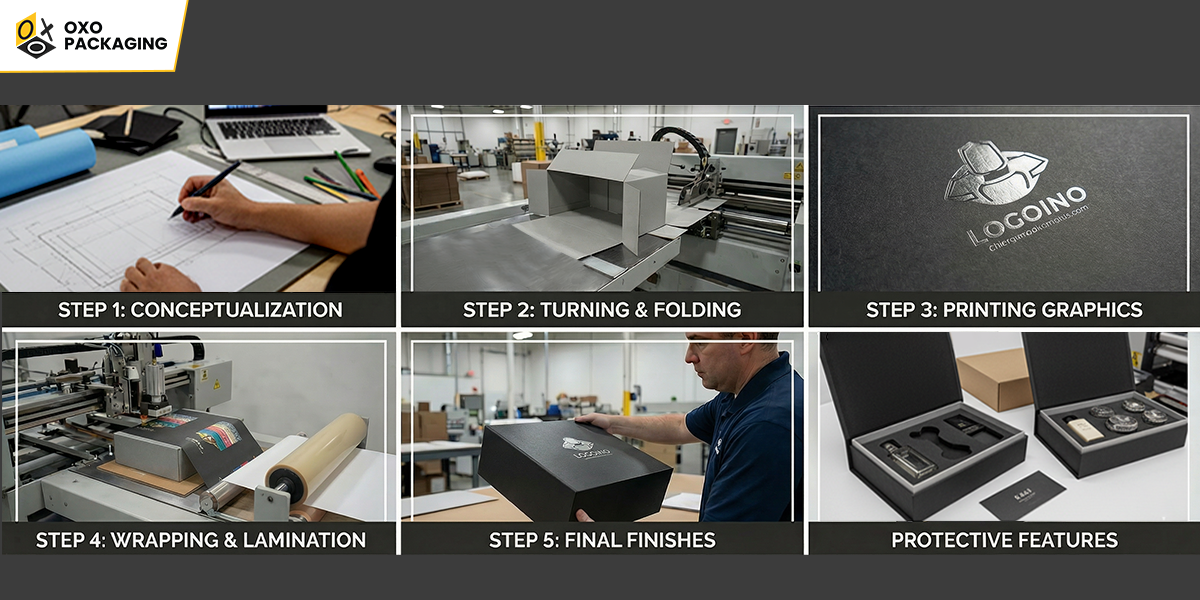

How Rigid Boxes are Made from Scratch? – Simple Step Guide

Curious about how the best-in-class boxes come into life, having no single flaw at any inch of the surface? Let’s get straight into the process of making a rigid box to finalize its finishes and beyond. Below are the common steps that are being followed for every box’s making.

Conceptualization

The development of the rigid box starts with the design, where the dimensions, creases and other vital measurement-related elements are determined. This tells whether the box will be square, rectangular or custom-shaped. Mostly all of the aspects are covered in this phase related to the material of the box.

Turning & Folding of Material

In the second, and another vital step, the pre-marked material is folded into multiple dimensions that lay the foundation of the box. From front to side walls, each of them is precisely tackled so there’s no error of even a single millimetre in between them.

Printing Graphics on the Surface

Well, this stage sometimes comes before the second one if there are more printing demands to cater to. Yet, if the graphics are fewer and there are no such requirements, then execute on the third step. Here, the compatible printing techniques are utilised as per the graphic needs.

Wrapping

Anything else, such as add-ons, is done afterwards as the box gets almost completed once it’s wrapped. Lastly, the box is coated with a laminated finish to develop a smooth or matte surface that protects the printed elements from fading.

Protective Features of a Rigid Box Packaging

Alongside the strong structure of the box from the outside, it can be further upgraded from the interior side to ensure the products don’t roam while moving. The common securing features can be:

- Properly cut inserts with precise fittings to accommodate the item in it. The material of these inserts can be paperboard, corrugated, moulded pulp, Styrofoam or even plastic.

- Dividers to organise multiple product placements in a sophisticated manner,r preventing the scattering and poor presentation upon unboxing.

Should You Opt for Rigid Boxes?

The big question for your brand. Is rigid box packaging best for you or not? Well, it can be or can’t. The actual answer depends upon your brand’s product collection and the target customers.

If you’re selling high-end luxury products that only a specific audience buys, giving them personalisation is the only way to stand out. To stand out as a competitive brand, you should go for the rigid boxes as they’re your key to the brand’s success and not a way around.

In contrast, if you’re selling cheap and low-end products, you aim to generate high sales numbers rather than focusing on individuality. Then, rigid boxes may not fit your packaging, or in fact, they may cost more than your actual product. So, it’s a clear indicator of whether you consider them for your packaging or not.

Whom to Contact to Get Reliable Rigid Packaging Solutions?

Standing out in the competitive market isn't child's play. Especially when there's a giant, already deep root of their brands for years. Shaking them from the foundations is not feasible for new, striving brands; that’s why they must adopt a strategic approach to deliver something exceptional.

Custom packaging is one factor that makes them distinctive and set apart from the rest of the competitors. Unfortunately, finding and partnering with a reliable vendor is a hectic task you may face. But don’t worry. At OXO Packaging, we’re the trusted custom packaging vendor catering to all kinds of rigid boxes needs.

From creative design to practical add-ons, our custom-printed boxes are built to shine on the shelves and beyond. You can contact us anytime by calling (02) 7228 8555 or writing to sales@oxopackaging.com.au for a custom quote.

Last Words

All in all, now you’re equipped with the right knowledge on rigid packaging and can easily determine whether you need them or not. With the predicted trend to reach a market value of USD 98.1 billion by 2035, rigid packaging will remain in the limelight among all industries for a long time. Still unsure whether to count on it or not? Consult with an expert rather than relying on guesswork. That’s all from our side, now it’s your turn!

The actual cost of a rigid box depends upon the material, size, printing and add-ons. It ranges from affordable to expensive options for most, but they’re costly compared to other kinds of packaging.

Well, the rigid boxes made from recycled paperboard materials are sustainable as they’re environmentally friendly. If it’s from Kraft, they’re compostable leaving minimal carbon footprints.

There are multiple reasons why the top brands consider luxury packaging as their finest and most fantastic packaging option when compared to their peers. Also, it aligns with their brand theme that they can’t take the risk of going with an ordinary box and risk their reputation at any point.

Not at all. The boxes made from corrugated materials are mainly used for bulk shipping purposes. Whereas the rigid boxes are more personalised and offer a top-notch presentation.

The design of the boxes will change as per the demands of the users and product dimensions. For instance, the trendiest designs will be:

- Minimalist Boxes

- Innovative Geometrical Shapes

- Mechanism Designs

- Smart Features Integration

- Heritage-Inspired Rigid Box

For most rigid boxes, they are made from chipboard and sturdy materials to develop a bespoke solution that stays in its shape and doesn't lose the structural integrity. While it’s covered with a paper wrap to enhance the outer look.

Indeed. Rigid boxes are one of the best options for online shopping brands to stand out and deliver their product in a uniquely crafted packaging.