Plastic pollution is pushing businesses and consumers to look for eco-friendly packaging alternatives. Among many alternatives, Polylactic Acid (PLA) is a material that has gained popularity in recent years.

PLA comes from renewable resources like corn starch and sugarcane. It offers a biodegradable and compostable solution for packaging needs. And the best part? PLA doesn’t compromise on functionality either.

Read this blog to learn more about PLA in detail. You’ll get to know about PLA benefits, challenges, applications, and future trends in the packaging industry.

What is PLA (Polylactic Acid)?

Put simply, polylactic acid (PLA) is a biodegradable and bio-based thermoplastic polymer made from renewable resources such as corn starch, sugarcane, and cassava. Unlike traditional petroleum-based plastics, PLA is compostable and reduces the carbon footprint of packaging applications.

How PLA Is Manufactured?

Polylactic acid (PLA) is produced through the bacterial fermentation of plant-based carbohydrates sources (raw materials such as corn scratch, sugarcane, and cassava) into lactic acid. Afterward, lactic acid is polymerized to create PLA.

Types of Polylactic Acid (PLA)

Since PLA is made from lactic acid, there are several types of polylactic acid:

- Poly-L-lactide (PLLA): originates from the polymerization of L,L-lactide. It is also known as L-lactide).

- Carbon Fiber PLA: blends PLA with carbon fiber which results in a stronger and more rigid filament.

- Blended PLA: PLA is mixed with other polymers to enhance properties and applications. Some common types are wood PLA and metal PLA.

Pros and Cons of PLA in Packaging Industry

PLA has its own pros and cons in the packaging industry. Exploring them will help businesses to drive insights whether they should choose PLA or not as their packaging material.

Pros of PLA

Polylactic acid is a superbly eco-friendly and sustainable packaging material. But it has also diverse benefits:

1. Polylactic Acid Biodegradable

Polylactic acid is 100% biodegradable and compostable, meaning it breaks down into natural components like water and carbon dioxide under industrial composting conditions. This makes it an excellent alternative to conventional plastics that take hundreds of years to decompose.

2. Reduced Carbon Footprint

Since PLA is derived from renewable agricultural sources, its production emits significantly lower greenhouse gases compared to petroleum-based plastics. According to research, PLA generates 65% fewer carbon emissions than traditional plastics, making it a climate-friendly choice for packaging manufacturers.

3. Versatility and Adaptability

PLA can be customised into various shapes and styles, making it suitable for a wide range of packaging applications such as food containers, beverage bottles, films, and wraps. Its transparency and durability allow it to replace materials like PET (polyethylene terephthalate) in many use cases.

4. Food Safety and Non-Toxicity

Polylactic acid is toxic-free material for food contact applications, ensuring that it is safe for packaging food and beverages. Unlike some petroleum-based plastics, it does not release harmful chemicals like bisphenol A (BPA) or phthalates, making it a healthier choice for consumers.

5. Compostability and Waste Reduction

One of the major advantages of PLA is that it can be composted in industrial facilities. Hence, it breaks down into organic matter within three to six months. This helps reduce plastic waste and promotes a circular economy where packaging materials return to nature rather than polluting landfills and oceans.

Cons of Using PLA in Packaging

Despite its many benefits, PLA also has some cons that need to be addressed for wider adoption in the packaging industry.

1. Composting Limitations

While PLA is compostable, it requires specific industrial composting conditions (high temperatures and humidity) to break down effectively. It does not degrade efficiently in household compost bins or landfill environments, leading to potential disposal issues.

2. Cost and Production Limitations

Compared to conventional plastic pouches, PLA is currently more expensive to produce due to the cost of raw materials and the polymerization process. However, with increased demand and technological advancements, production costs are expected to decline over time.

3. Heat Sensitivity

PLA has a lower melting point than traditional plastics, making it unsuitable for high-temperature applications. For example, PLA-based food containers may deform or lose their integrity when exposed to high heat.

4. Recycling Challenges

A question arises in the marketing industry: is PLA recyclable? Well, PLA is recyclable but it is not widely accepted in conventional recycling streams. Because it requires separate processing facilities. If mixed with regular plastic waste, it can contaminate recycling batches, leading to inefficiencies in waste management systems.

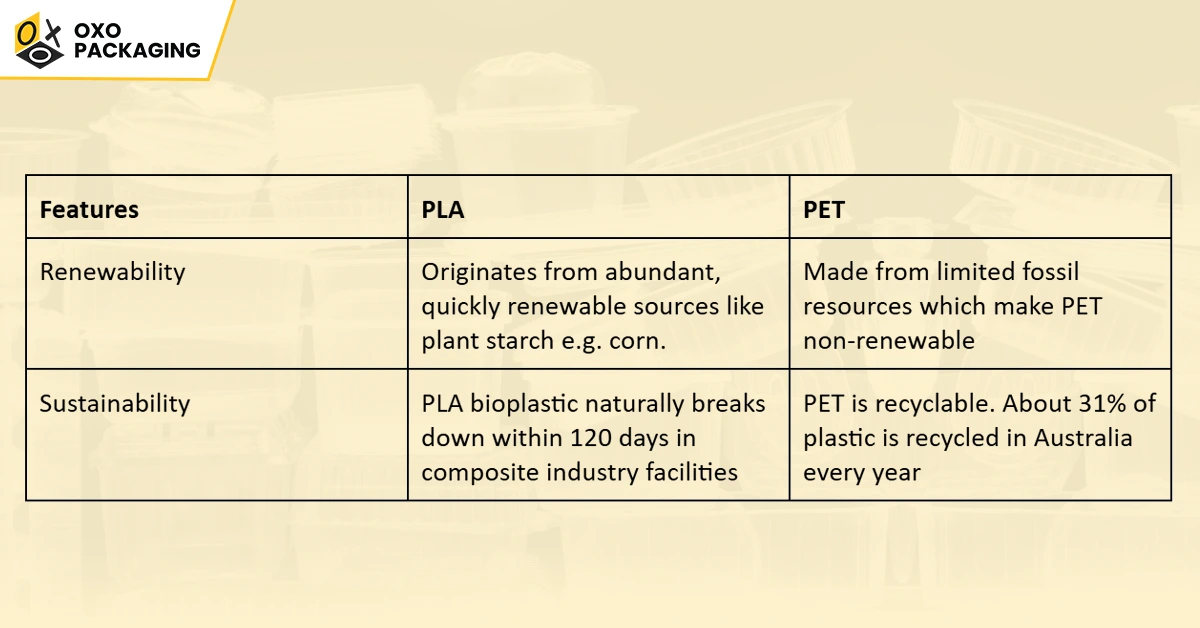

Polylactic Plastic vs PET

As a business owner, you must have known the basic difference between polylactic acid (PLA) and traditional polyethylene terephthalate (PET). Consider the comparative overview of PLA vs PET to understand which one is better in business interest:

Uses of PLA in Packaging Industries

The packaging industry has embraced PLA in various sectors due to its eco-friendly properties and functional advantages. Here are some key uses:

1. Food Packaging

PLA is widely used in food packaging applications such as clamshell containers, trays, cups, and cutlery. It provides an excellent oxygen barrier, helping to maintain food freshness. Being biodegradable, it is ideal for single-use food service packaging.

2. Beverage Bottles

PLA-based bottles are an alternative to PET bottles for water, juice boxes, and dairy products. They offer transparency and durability similar to traditional plastic bottles.

3. Flexible Packaging Films

PLA films are used for wrapping snacks, baked goods, and fresh produce. They provide moisture resistance and good printability for branding and labeling purposes.

4. E-Commerce and Retail Packaging

PLA-based mailers, pouches, and shopping bags offer sustainable alternatives for online retailers. Many brands are adopting PLA-based materials to align with their sustainability goals.

Future of PLA in Packaging

The global trend for sustainable packaging solutions is driving research and innovation in PLA-based materials. Some future trends include:

1. Advancements in PLA Blends

To overcome PLA’s limitations, scientists are developing blends with other biopolymers like polyhydroxyalkanoates (PHA) to improve mechanical strength, heat resistance, and decomposition rates.

2. Expansion of Composting Infrastructure

As the adoption of PLA grows, governments and industries are investing in industrial composting facilities to handle PLA waste effectively. Improved composting networks will enhance PLA’s viability as a sustainable alternative.

3. Cost Reduction Through Mass Production

With increased demand and production scalability, the cost of PLA is expected to decrease, making it more competitive with traditional plastics.

4. Enhanced Recycling Technologies

Innovative chemical recycling methods are being developed to convert PLA waste back into lactic acid monomers for reuse in new products, promoting a circular economy.

While challenges such as composting limitations and cost constraints exist, advancements in material science and waste management are paving the way for wider adoption.

Conclusion

Polylactic Acid is a desirable packaging solution. It is revolutionizing the packaging industry because of its sustainability characteristics. Businesses and consumers are adopting PLA packaging for the benefits it offers.

As a brand, you can boost revenue by adopting eco-conscious packaging solutions. You’ll be able to attract more consumers with eco-friendly packaging. Contact us today to get a free sustainable packaging quote for your business needs.

PLA stands for Polylactic Acid, a biodegradable plastic made from renewable resources like corn starch, sugarcane, or cassava. It is widely used as a sustainable alternative to traditional petroleum-based plastics.

Yes. PLA is biodegradable and compostable under industrial composting conditions, typically breaking down within 3 to 6 months. However, it may not degrade effectively in home compost or landfill environments.

PLA is used to make:

- Food containers & clamshells

- Cups & lids

- Bottles

- Clear bags & films

- Straws

- Cutlery

Its transparency and durability make it popular for food-safe and eco-friendly packaging.

- Made from renewable resources

- Biodegradable & compostable (industrial compost)

- Reduces carbon footprint compared to traditional plastics

- Safe for food contact

- Offers clarity and rigidity similar to PET plastic

PLA has low heat resistance, softening at around 50°C to 60°C (122°F to 140°F). It is not suitable for microwaving or high-heat applications.

Yes. PLA is certified food-safe for cold and room-temperature food applications, commonly used for salad containers, cups, and takeaway boxes.

PLA combines eco-friendliness, renewable sourcing, and functional properties, making it an attractive solution for brands aiming to reduce their environmental impact and meet consumer demand for sustainable products.